Introduction to Gearbox Syncro

In the realm of automotive engineering, the term gearbox syncro resonates with significant importance. Gearbox synchronization is an intricate yet essential process that ensures smooth gear transitions in vehicles. Understanding how gear synchronization functions and its pivotal role can greatly enhance your driving experience, extend the lifespan of your vehicle, and potentially save you money on repairs.

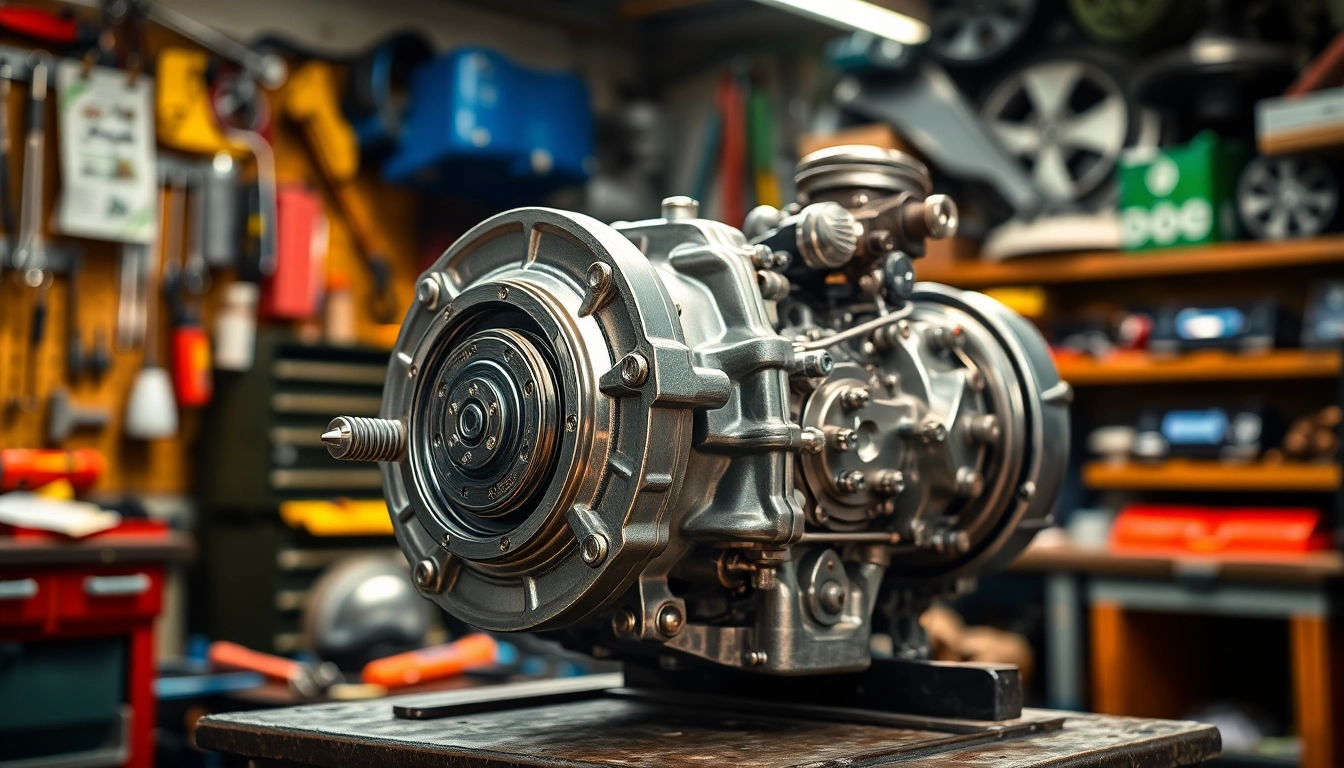

What is a Gearbox Syncro?

A gearbox syncro, short for synchronizer, is a vital component within a gearbox system that aids in matching the speed of the gear and the speed of the output shaft during gear changes. This mechanism is instrumental in enabling smooth engagement of gears, preventing grinding, and providing an efficient transfer of power from the engine to the wheels. Syncros typically consist of a set of cone-shaped friction surfaces, allowing for the friction necessary to synchronize the speeds of the engaged gears before they mesh.

Importance of Gearbox Syncro in Vehicles

The importance of gearbox syncros cannot be overstated in modern vehicles. A functional syncro allows for seamless gear transitions, enhancing the overall performance and drivability of the vehicle. This component also plays a crucial role in prolonging the life of both the gearbox and the engine, ultimately reducing maintenance costs. For performance vehicles, an efficient syncing system is fundamental to achieving optimal acceleration and responsive handling.

Common Types of Gearbox Syncros

Gearbox syncros can be categorized into several types depending on the design and application. The most common types include:

- H-series Syncros: Primarily found in manual transmissions, these syncros utilize a cone design to facilitate speed matching.

- Dog Engagement Syncros: Typically found in racing cars, these syncros offer a more aggressive engagement mechanism for quick shifting.

- Multi-cone Syncros: Utilized in high-performance vehicles, multi-cone syncros enhance friction and stability during gear changes.

The Mechanics of Gearbox Syncro

How Gearbox Syncro Works

At its core, the functionality of a gearbox syncro revolves around friction and rotational speed. When a driver initiates a gear change, the syncro temporarily links the two gears, matching their speeds before engagement. The cone shape of the syncro induces friction, which slows down the faster gear or speeds up the slower gear, facilitating a smooth transition. This process helps to reduce wear on the gearbox components and ensures that the vehicle operates efficiently.

Materials Used in Gearbox Syncro Construction

Gearbox syncros are engineered from a variety of materials that focus on durability and performance. Common materials include:

- Bronze: Frequently used due to its low friction properties and excellent wear resistance.

- Composite Materials: Increasingly popular for their lightweight yet durable characteristics, enhancing overall performance.

- Stainless Steel: Offers high strength and resistance to corrosion, making it suitable for many automotive applications.

Understanding Gear Engagement with Syncros

For gear engagement to occur successfully, it is essential that the syncro not only matches the speeds of the engaged gears but also ensures proper alignment. Misalignment can lead to gear grinding, which may cause significant damage to both the syncros and the gears themselves. Hence, regular maintenance checks are crucial for maintaining the integrity of the gearbox and its components.

Diagnosing Issues with Gearbox Syncro

Common Symptoms of Syncro Problems

Recognizing issues with gearbox syncros early can prevent further damage and costly repairs. Common symptoms include:

- Grinding Noises: Often indicates that the gears are not fully engaging due to syncro failure.

- Difficulty Shifting: Resistance while attempting to change gears is a clear sign of syncro problems.

- Unintended Gear Slips: A syncro that isn’t functioning properly can cause a gear to slip unexpectedly, compromising safety.

Tools for Diagnosing Gearbox Syncro Issues

Diagnosing gearbox syncro issues typically requires specialized tools, including:

- OBD II Scanner: Helpful for reading error codes that may indicate gearbox issues.

- Transmission Fluid Tester: Allows for analysis of the transmission fluid’s condition, as fluid contamination can signal syncro problems.

- Gearbox Inspection Tools: Essential for visual inspection and testing of the syncros and associated components.

Best Practices for Maintenance and Care

Regular maintenance is key to ensuring the longevity and functionality of gearbox syncros. Recommended best practices include:

- Regularly checking and changing transmission fluid to prevent contamination.

- Keeping the gearbox properly lubricated to reduce friction and wear.

- Scheduling routine inspections to identify early signs of wear or damage.

Upgrading or Replacing Gearbox Syncro

When to Consider Upgrading Your Gearbox Syncro

Deciding to upgrade your gearbox syncro may be warranted in several scenarios:

- Performance Enhancements: If you’re modifying your vehicle for increased performance, upgrading to high-performance syncros can provide better gear engagement.

- Frequent Issues: If you consistently experience syncro-related problems, it might be time for a more permanent upgrade.

- Age of Vehicle: Older vehicles may benefit from modern syncro technology that offers improved efficiency and durability.

Replacement vs. Repair: Making the Right Choice

When faced with syncro issues, vehicle owners often struggle with the decision of whether to repair or replace the component. Key factors to consider include:

- Cost-effectiveness: Sometimes, replacing a faulty syncro may be more cost-effective in the long run compared to repeated repairs.

- Extent of Damage: If the syncro is severely damaged, replacement is usually the more prudent choice.

- Vehicle Value: For high-value or performance vehicles, investing in replacement syncros can ensure optimal performance and resale value.

Steps for Successful Gearbox Syncro Installation

When it becomes necessary to install new gearbox syncros, follow these steps for a successful installation:

- Ensure the vehicle is safely positioned and check the relevant service manual for specific guidance.

- Remove the gearbox from the vehicle, taking care not to damage other components.

- Disassemble the gearbox casing to access the syncros, noting the arrangement of components for reassembly.

- Replace the old syncros with the new units carefully, ensuring the correct alignment and fit.

- Reassemble the gearbox, double-checking that all seals and gaskets are in good condition.

- Reinstall the gearbox into the vehicle and perform a functional test to ensure proper operation.

Performance Benefits of a Functional Gearbox Syncro

Enhancing Driving Experience with Proper Syncros

A well-functioning gearbox syncro dramatically improves the driving experience by providing smooth and precise shifts. This ensures that drivers can maintain control of their vehicles, especially during high-stress driving conditions, such as racing or off-roading.

Long-term Efficiency Gains with New Gearbox Syncros

Upgrading to new gearbox syncros not only enhances the immediate driving experience but also contributes to long-term efficiency. A new syncro can lead to reduced fuel consumption due to minimized power loss during gear changes, translating to savings at the pump.

Real-world Examples of Gearbox Syncro Enhancements

Many vehicle enthusiasts have experienced significant performance improvements after upgrading their gearbox syncros. For example, a major automotive brand reported a 15% increase in acceleration response in their performance models after implementing upgraded syncro technology, showcasing the tangible benefits of investing in high-quality syncros.